Items needed to make your own leads.

Stainless Steel Pan

Stainless Steel Ladle

Heat Resistant Gloves

2oz Inline Dumpy Dice Mould

Lead Mould Clamp

Plastic Inserts

Lead Coating Powder

You can visit Pauls Angling Supplies on Ebay for all these items and more.

Making your own lead weights is quite an easy thing to do and at well over a pound each in the tackle shops you can make a good saving over a period of time. There is an initial outlay of about £15 for a lead mould, but you can soon make that money back and save yourself quite a bit in the long run.

Lead moulds are available from most good tackle shops. Personally, I get mine from Stapeley Water Gardens in Cheshire although Ebay is also worth a look for Lead Making Moulds

The lead making process itself is actually quite easy, firstly the lead has to be melted down, I use on old pan on the stove to do this, as you can see in the picture, I just put a small piece of lead pipe into the pan and leave it to heat up, eventually it will melt.

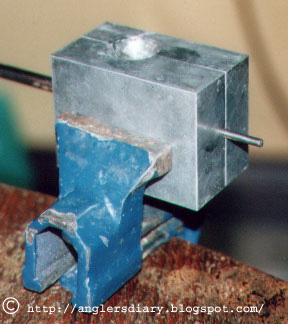

Whilst the lead is melting, I heat the lead mould in the oven for a while, this is for safety, pouring molten lead into a cold mould is dangerous as the lead can 'spit'. If the mould is heated up, this doesn't happen. After this, I set the mould up in a small bench vice, this one has a 'G' clamp underneath and just clamps on the end of a table, it cost me £1 from a shop called 'poundland'!.You can also get a custom Lead Mould Clamp

When the lead is all melted, I scrape off any excess dirt/crap from the lead whilst it's in the pan, then scoop up some molten lead and poor it into the mould. I have the mould located right next to the cooker whilst doing this, that way I don't have far for the spoon to travel, this minimizes the risk of spilling any lead and makes sure it's really hot when being poured. Some people prefer a pan with a small 'V' type recess so they can just pour straight from the pan, the large spoon I'm using here has a similar recess.

I wait until the lead is set, which is just a few seconds, then remove the mould from the vice and open it. This should be done with gloves on as the lead and mould are both still very hot at this stage. The bar can be removed and after leaving to cool for a while, the 'extra' bit of lead formed by the funnel of the mould can be cut off and the lead filed down to remove all traces of it. Whilst waiting for the lead to cool, I can set up the mould again and make some more.

When the filing is complete, the leads should be ok to use as they are, needing just the Inline Tubing Insert

I don't like to leave my leads at this stage, preferring to coat them with Lead Coating Powder

It's then just a case of putting it back over the stove, as you can see, the powder melts into a coating. By turning the bar, I can heat and melt all the powder. After completing, I can trim off any excess plastic coating from were the bar is on either end of the lead and I'm left with a perfect inline coated lead weight.

That's basically it for the making leads, the only thing I'd like to add is BE CAREFUL molten lead is extremely hot, and you should strive to do this job as safely as you can, have some gloves handy, make sure you are in a well ventilated area and preheat your mould before making your first lead. Basically, use your common sense!.

Items needed to make your own leads.

Stainless Steel Pan

Stainless Steel Ladle

Heat Resistant Gloves

2oz Inline Dumpy Dice Mould

Lead Mould Clamp

Plastic Inserts

Lead Coating Powder

You can visit Pauls Angling Supplies on Ebay for all these items and more.

Mark

Excellent explanation I’m making some barrel leads for sea fishing just get the lures down in a heavy tide and have ordered mold and plastic insert from Paul angling supplies , so think you’ve answered all my questions thanks

ReplyDeletegood luck mate, be very careful when you make your barrel leads, molten lead is nasty and you need to take the utmost care, make sure you're in a well ventilated area and don't spill a single drop!.

ReplyDelete